Description

Machine VC9-1612 is a cutting complex for textile, footwear, leather, and other industries and industries processing lumpy, rolled, natural, synthetic and multilayer materials, which is based on a cutting plotter with a vibroknife – a modern technology for cutting soft, loose, easily deformable materials, while maintaining high cut quality, speed and precision.

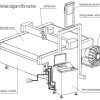

The machine has a classic portal design with a cutting system installed on the portal, consisting of a vibroknife and additional equipment. The working head has an interchangeable tool installation and allows you to cut with 5 types of blades, or apply a pattern with a marker, as well as punch / stamp small holes (perforate with quick removal of scraps), equipped with a steaming system for smoothing textiles during high-speed cutting / stamping.

The cutting takes place on a working table, which has a sectioned vacuum pressure zone to hold the material during the cut. The material is placed on the table by hand. The software, compatible with DXF and CAD systems in formats, has the ability to optimally calculate the cutting according to the specified dimensions with a minimum amount of waste / trimming, while allowing the operator to visually edit / change the result of the calculation, for which the machine uses a laser projector that highlights the pattern of cutting lines and thus, making the layout of the entire cutting visible during a preliminary examination directly on the material. This greatly speeds up the process of setting up the machine, practically eliminates errors in the calculation.

In addition to the main task of forming a cutting pattern and the operation of knives, the modern intelligent software of the machine controls all aspects of its operation: it maintains an interface, a database, controls the work, making the necessary settings when performing certain tasks, and links these machines into a single complex under general remote control, correct and update online information for operators. The built-in network system provides data transfer from the ERP system for efficient control of production processes and labor productivity on each machine. For the safety of work, the working area of the machine has a system of optical sensors that control its boundaries during operation.

In terms of technical equipment and functionality, the machine is suitable for small and medium-sized industries, has the ability to integrate into production lines, has high results in terms of workmanship and performance.

| Model | VC9-1612 |

| Working field size, mm | 1600 x 1200 |

| Cutting thickness, mm | 12-18 |

| Cutting speed /maximum/, mm/s | 1000 |

| Travel speed /maximum/, mm/s | 5000 |

| Tolerance, mm | 0.05 |

and the total space occupied, mm 2200 x 2400 x 1300 /table with portal/

from 2786 x 2380 x 2290 Weight, kg 800

Options

Set contents /standard/

– machine

– projector

– vacuum table

– computer rack with installed software

– compressor

– connecting wires and hoses

Reviews

There are no reviews yet.