Description

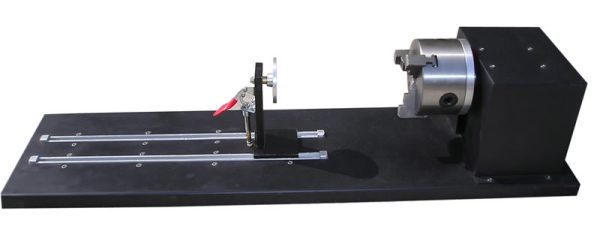

One of the most common specialized mechanisms is a rotary device, which significantly increases the capabilities of the machine.

The rotator can rotate parts 360° during the machining process. Installing a rotary device (rotary axis) on laser / milling and plasma machines makes it possible to carry out high-quality cutting, engraving and marking on workpieces having the shape of a body of rotation or even without an axis of symmetry.

By rotating the workpiece with high angular accuracy, you can easily display on details of any complex pattern or text, make a complex cut, while maintaining high resolution and excellent quality on such items as, for example, a cup, glass, bottle, vase, etc.

Fixing a simple workpiece is carried out in a three-jaw self-centering chuck and asymmetrical workpieces, fixation is carried out with the help of a stop in an adjustable tailstock. The rotary device is easily installed and fixed in the working area of the machine /spindle/ or can be mounted in the mode of quick replacement of one of the controlled axes of the machine, without reloading the control system.

Rotary devices differ in the type of motor, diameter and length, as well as the system for fixing the workpiece. The choice of rotary device will depend on the desired processing criteria and the compatibility of the model with your machine.

| Item length | Up to 350mm |

| Object diameter | Up to 100mm |

| Power supply | 220V/ 50Hz |

Options

Reviews

There are no reviews yet.